School: ITE College West

Team members: Tan Chong Der, Jerome Yap, Wilson Tng

The “Detachable Camera Mobile Phone” (DCMP) explains how feasible this mobile phone can facilitate National Service men to stay connected in places which are highly secured and restricted. By designing a detachable camera phone cum re-attach abilities such security problem will be overcome thus allowing National Service men to stay connected and communicate effectively without any hindrance.

INTRODUCTION

The aim of this project from the Create Factory team is to develop a viable proof of concept for a detachable mobile camera phone use in a highly secure environment. This newly innovative product will be made user-friendly and available in places such as the military bases or places that prohibit personnel from having camera mobile phone.

This unique camera phone has few distinct functions such as water and shock resistant features. The camera itself can be easily detachable from the phone and replace with a blank housing cover. This will allow seamless mounting of blank cover upon the removal of the camera casing without the hassle of acquiring additional non camera mobile phone.

Scope

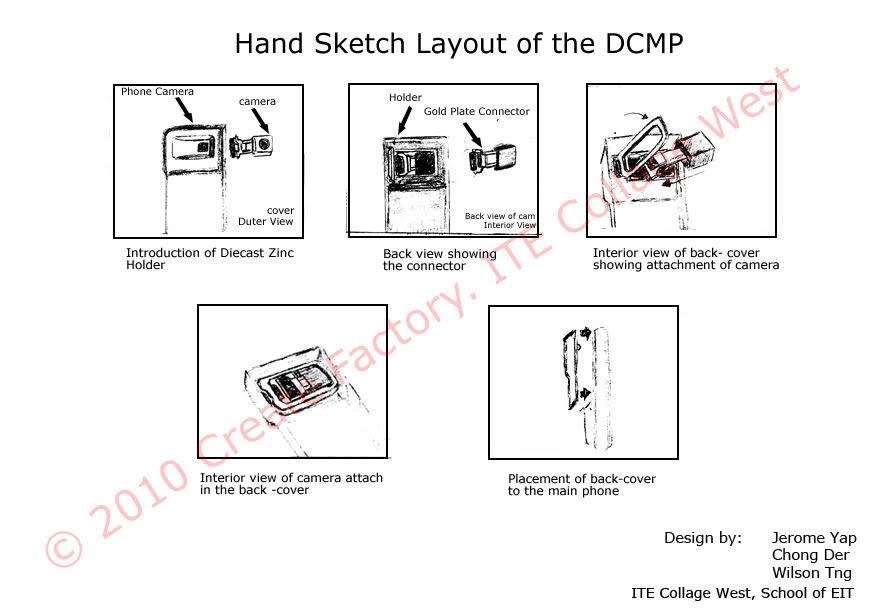

The Project team has completed an analysis to determine most profitable design on mobile phones. The design analysis was made on the material used with the highly recommended material for stainless steel which has the ability to withstand external shocks whereas a polycarbonate cover absorbs shocks on the body of the mobile. For additional protection, we ideally deduced that the cameras side holder should be made of die-cast zinc to withstand impacts and help to secure the external slot cover.

Site design

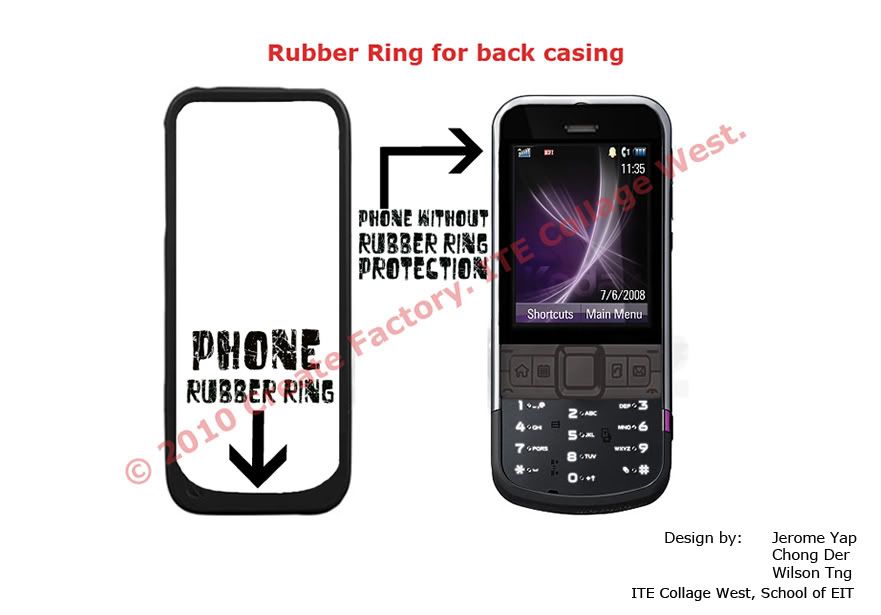

Further to our thorough research to mitigate the water absorption on the camera mobile phone, a fine rubber ring will be fitted at the edge of the camera casing. Similarly this rubber ring application will be applied at the loudspeaker and microphone compartment.

Site design

Technical Background

The design of this DCMP camera is developed with the following hardware configuration

- External DCMP housing dimension “10.2” cm x “5.4” cm

- Water & Shock resistant

- Rubber Ring

- 3.2 Mega Pixel CCD(Charge Coupled Device) sensor camera

- 2x Optical Zoom, 5x Digital Zoom

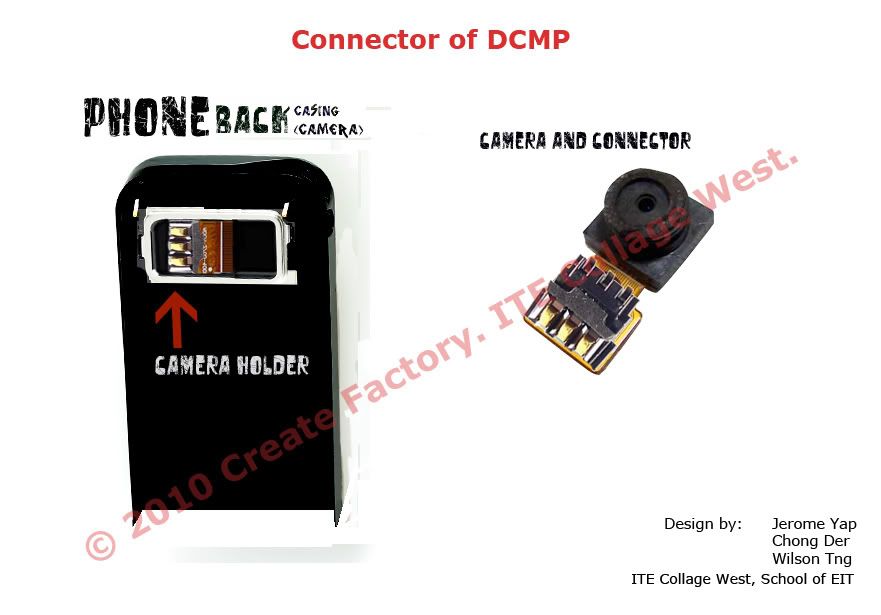

- Using 3 pin mini gold plate Connector (for battery, USB)

Layout of DCMP

A customise prototype structure comprises of a 3 pin connector and rubber is shown in this site

Drop/Shock Test

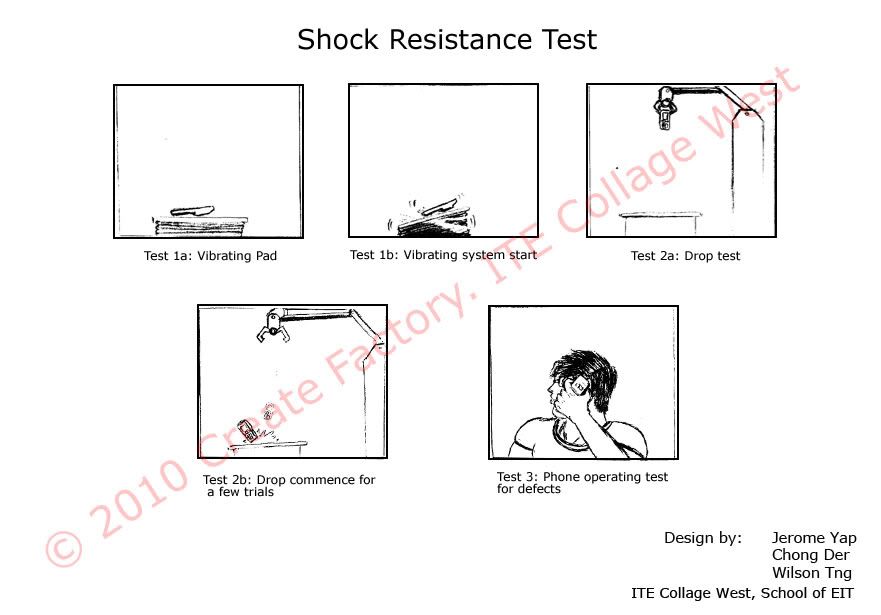

A detailed test plan for firmware and hardware will be performed such as a gradual dropped of the DCMP phone during operating mode from a height of 1.50 meters (4.9 feet). Refer to site test plans, namely vibration and height tests:

a) Vibration and shock test

b) Drop test

Similarly, the water resistance test plan will involve the DCMP phone to undergo a rigorous water penetration test with duration of 30 minutes power on. All these tests include harsh environment and material test (anti-rust on stainless steel and resistance against water entering into the circuitry board).

Download the site water penetration test plan

0 comments:

Post a Comment